A Continuous Process is and Incurs High Cost Operations Management

October 8 2021

Continuous Manufacturing Explained: How to set up and maintain a continuous production system

Manufacturers use various production setups to be efficient at mass production. A continuous production system is one of them and comes with distinct benefits, challenges, and maintenance requirements.

What is continuous production?

Continuous production, otherwise known as mass production, is one of three main manufacturing methods – the other two being batch and job production. It is used to manufacture large quantities of products with few variations and relies on highly standardized processes, process sequences, tools, and equipment.

In a continuous production system, the material flows through a series of operations without pause, with optimized and constant material handling. Naturally, the workforce has to operate 24/7, in rotating shifts. It is the only way to manage quality issues and product waste.

Continuous production examples in different industries

Continuous production systems are used by operations that can maximize the advantages of continuous production flow. Below are some specific examples.

Automotive

With automotive manufacturers better known for process production, the Toyota Indonesian manufacturing facilities are a good case study in continuous production. Comprising three integrated plants, the facilities work as one, casting metal, stamping it, building engines, assembling vehicles, and packing – in one long and complex example of continuous production application.

Pharmaceuticals

Pharmaceutical companies were known for batch processing. However, many have started to move towards continuous production.

The manufacturing system produces coated tablets from raw powders in a continuous production stream. It allows several continuous streams of roll compaction or wet granulation to offer specialized solutions to clients' needs. GlaxoSmithKline recently opened two new continuous manufacturing facilities in Singapore and expanded the third one, following a $95 million investment.

Mining and metals

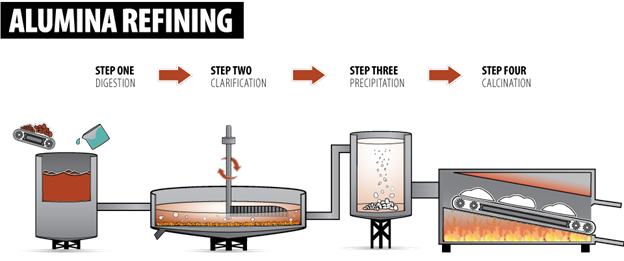

The mining and metals industries use continuous production to extract and transform raw materials. A global leader in aluminum production, Rio Tinto mines the mineral bauxite, transforms it into alumina, which is the key constituent of aluminum. It is sent to aluminum smelters for conversion to metal.

Alumina refining process – Source: Aluminimum.org.au

Biotechnology

Biotechnology uses living organisms and molecular biology to produce various products, including genomics, food production, medicine, and biofuels. In 2019, Sanofi opened the world's first digital facilities using intensified, continuous biologics production to produce therapeutic products.

Continuous process versus batch manufacturing

Many small to medium-size manufacturers begin as jobbing shops, producing a diverse range of customized products, where a person or a team manufactures a product from start to finish before beginning the next.

As the business grows, they need to focus on efficiency. In essence, they need to decide which type of manufacturing process to commit to. The decision is based on factors like product demand, the state of raw materials, and available resources.

The discussion often comes down to batch vs continuous manufacturing, so it is worth taking a minute to learn the differences.

Batch manufacturing process

Batch manufacturing uses a stop/start manufacturing process where products are manufactured in groups or batches. Such production may be:

- demand-led: due to smaller production runs required for a specific product

- quality-led: due to the need for stringent checking of product conformity to set standards

The period between batches is known as cycle time, and it facilitates any changes required in material specification, process adjustment, or maintenance interventions.

Batch manufacturing is less disrupted by machine breakdown as jobs may be shifted between workstations. It also limits financial losses from quality deviations by minimizing scrap quantities. However, lower machine utilization rates can offset the gains in quality and operational flexibility.

Continuous manufacturing process

Continuous production does not cease, with raw materials and work-in-progress in continuous motion. Conveyor belts and pipelines become moving storage facilities, lessening warehousing and stockpiling requirements.

The driver for continuous production is partly due to the capital intensity of the process requiring high machine utilization to buffer costs over larger production quantities. Yet, many of the processes themselves cannot stop and restart without incurring significant penalties (there is a great risk of settling suspended solids or crystallization and hardening of materials in piping and tanks).

Frequent stoppages also increase cycle times, thermal cycling, and pressure cycles on equipment, increasing fatigue and shortening its useful life.

Unlike batch production, maintenance and equipment upgrades on continuous manufacturing facilities will occur annually – at best. Some plants operate two to three years without stoppage, and high-temperature transformation systems such as blast furnaces run without pause for five to ten years.

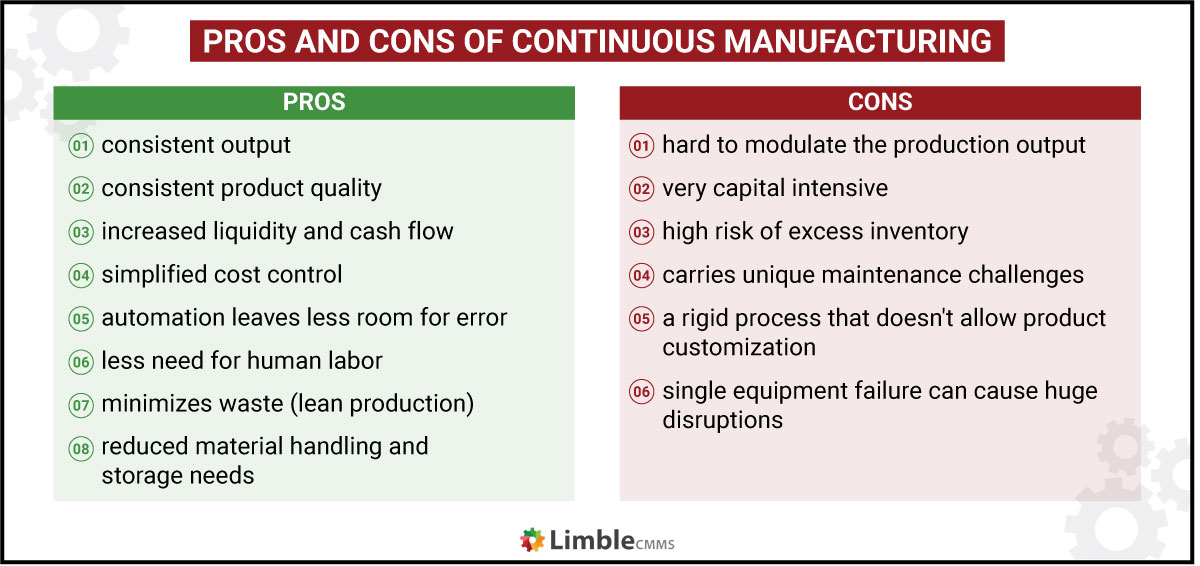

The pros and cons of continuous manufacturing

We already touched on some pros and cons while explaining the process, but let's systematize all of the points in one place.

Advantages of continuous production:

- Strict process control and monitoring ensure consistent product quality.

- Utilizing just-in-time delivery of raw materials and balancing of manufacturing sequences reduces work-in-progress. This reduces business risk and provides financial benefits such as increased liquidity and improved cash flow.

- Reduced material handling and storage areas lower plant construction capital costs and material handling investment requirements.

- Material cost control is simplified.

- Given the capital intensity of continuous production, amortization of capital costs over high production rates allows a lower capital cost per unit.

Disadvantages of continuous production:

- The process of continuous flow necessitates a standardization of products, locking in a rigidity that makes it harder to customize products to changing customer needs.

- The interdependence of sequential production flows reduces fault tolerance, with a single equipment failure stopping or creating severe disruptions to product volumes.

- Continuous production is demand-sensitive. Used where there's a high or continuous demand for a product, there is little ability to modulate production flows when demand falters or drops.

- Investment in advanced, expensive, and often customized equipment makes the production process very capital-intensive.

- Carries a high risk of excess inventory holding in the event of a downstream disruption.

If it wasn't obvious already, one of the challenges of continuous manufacturing is its unique maintenance requirements. As a system with a single point of failure that needs to operate 24/7, continuous production needs a well-thought-out monitoring and maintenance plan.

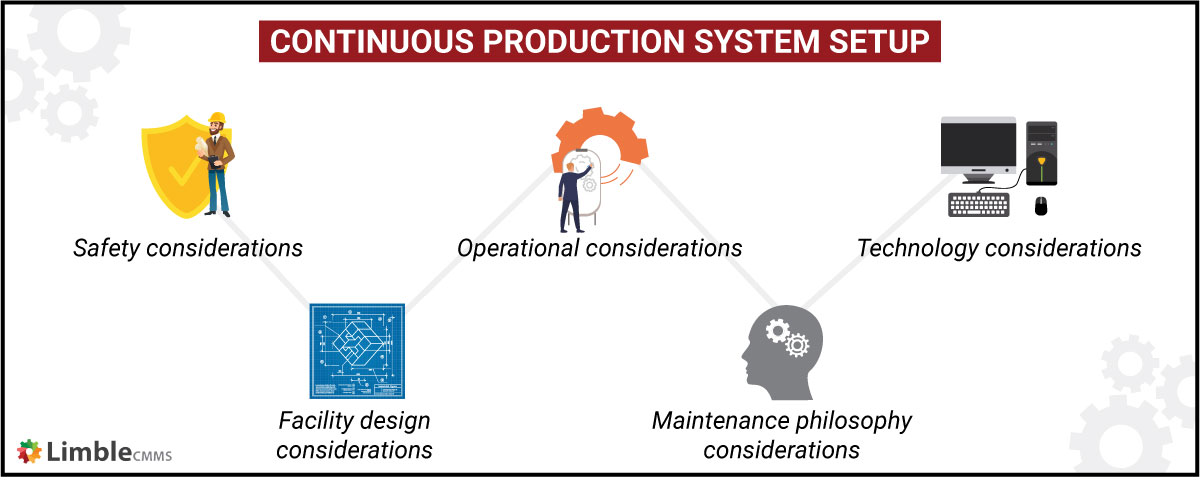

The maintenance requirements of continuous production plants

Plant and process design, maintenance philosophies, strategies, tactics, and operational interventions require serious consideration given the complexity, criticality, and 24/7 nature of continuous manufacturing.

Facility design considerations

The above-mentioned considerations often occur only after the plant has been built and operations staff employed. To increase the maintainability of a continuous production plant, engineering and maintenance assessments should happen during the design phase of the manufacturing asset/plant.

With maintenance interventions planned annually at best, the in-service reliability of the individual equipment should be factored into the total cost of ownership (TCO) decisions that drive purchasing recommendations.

Similarly, one should perform FMECA studies into process flows to drive decisions on factory layout, equipment redundancy assessments, and spares inventory.

Maintenance philosophy considerations

The maintenance philosophy will require thought. It is highly recommended to perform reliability-centered maintenance before committing to one or a mix of maintenance strategies and technology.

Some manufacturers might also want to look into total productive maintenance and business-centered maintenance. They both feature many interesting practices, some of which might be a good match for your operational needs.

In general, strategic decisions on reactive, preventive, condition-based, and predictive maintenance will evolve from the RCM, FMECA studies, and a maintenance philosophy selection.

In continuous production facilities, preventative maintenance will usually occur in paralleled processes providing system redundancy. Condition-based maintenance practices will form the bulk of the strategy given the infrequency of maintenance shutdowns. Predictive and prescriptive maintenance will target the assets incurring high costs from downtime or maintenance.

Technology considerations

RCM, as well as predictive and prescriptive maintenance, demand extensive and comprehensive data collection, storage, and analysis.

Aside from specialized software, companies can use modern CMMS systems to manage condition and performance data coming from continuous production assets. Before that, assets have to be retrofitted, or come with, proper sensor equipment.

Giving insight into the maintenance function, a CMMS reduces the need for reactive maintenance interventions, which can have prohibitive cost implications in a continuous production system.

When coupled with predictive maintenance analytics, CMMS users can look at deterioration trends to predict when the asset will fail. This way, maintenance planners and managers have plenty of time to allocate the necessary resources and schedule maintenance – which is extremely beneficial in the context of continuous manufacturing.

Operational considerations

Planned downtimes are very far apart and there is a high time pressure on the length of such shutdowns. This can seriously complicate the decisions on maintenance staffing.

Should you keep maintenance in-house or outsource everything? It will largely depend on the cost and availability of suitably qualified contractors. This is a very important decision as it directly impacts the size of your spare parts inventory, securing access to specialized tooling, and the arrangement of other internal resources.

Lastly, technology obsolescence and equipment upgrades also require careful consideration to ensure they are appropriately planned, resourced, and scheduled.

Safety considerations

While safety is a critical component of all maintenance interventions, maintenance shutdowns at continuous production facilities require extra planning. With strict time constraints, the economic pressures of exceeding planned shut deadlines create commercial pressures.

What do safety incidents and equipment failures have in common? They are both often caused by human errors. And those errors are more likely to happen when you're in a rush.

That's not all. A planned maintenance shutdown of a continuous production system will require multiple trades to work in close proximity or over and under each other.

Testing by one maintenance team must be carefully choreographed with others in the area to avoid exposure to moving equipment, electricity, or stored energy. It is paramount that workers follow LOTO guidelines and other safety procedures.

Continuous production facilities such as chemical plants will have additional safety concerns to address during maintenance shutdowns. Some chemicals require continuous circulation, agitation, or heating – even while shut down for maintenance. Tie-ins or cut-ins for upgrades or replacement will expose maintenance crews to danger. Planning for such maintenance periods typically begins months, or even years, ahead of time.

How to set up a continuous production system

With the capital intensity and complexity of sizable continuous production facilities, planning and preparation are key. However, even a small to medium-sized manufacturer seeking to move to continuous production from jobbing or batch manufacturing will need to do some serious thinking.

Initiating a project mindset for such a setup is useful.

via GIPHY

1) The feasibility phase

Headed by an individual with in-depth knowledge of production, a feasibility phase should be planned and funded with cross-organizational representation. Key roles involved in the planning phase would include production, engineering & maintenance, financial, quality, and safety personnel.

2) The planning phase

The required decisions will begin with the manufacturing philosophy that drives equipment selection. Highly standardized products in high volumes allow specialized or single task equipment selection or manufacturing:

- Is there a facility to use multi-role equipment to provide redundancy or backup?

- How likely is a change in product specification or client requirements?

These decisions often call for a trade-off between capital expenditure now and potential operational expenditure in the future.

Control and monitoring strategies are crucial in continuous production, where maintaining quality within an operating line allows timely intervention from alerts or advisories, ensuring consistent in-specification output:

- How will sampling be enacted?

- Using process analytical technology (PAT), will process measurements utilize sensors to measure the performance attributes of the process itself or raw in-process material quality that software may translate into the required attributes?

- Will sampling be online, at-line, or off-line?

Each selection will drive decisions on technology and personnel, mitigating the risk of non-conforming products.

3) The implementation phase

When everything is mapped out, the "only" thing left to do is put things into motion. Setting up a manufacturing plant can be an article in itself so we will not even try to wrestle with that here.

During the implementation phase, keep a strong focus on the interconnectedness of the devices and the technology you use. The ability to produce, store, track, and analyze asset data will be key for optimizing the production process.

Your maintenance software should be linked with asset condition and performance data, predictive analytics, as well as inventory and planning systems. This way, the pre-maintenance-shutdown preparation will ensure workload leveling, skill requirement identification, spares availability, and correct maintenance and upgrade task scheduling.

Summary

Continuous production manufactures large quantities of products with few variations, relying on high levels of standardization of processes, procedures, tools, and equipment.

With material in continuous movement through a series of operations, and a workforce operating 24/7, the cost impost, quality issues, and product waste resulting from stoppages demand comprehensive design and maintenance considerations.

With equipment downtime restricted to infrequent maintenance shutdowns, the design of a comprehensive maintenance strategy – supported by targeted data collection and analysis using a modern computerized maintenance management system – are the minimum components required to create a sustainable continuous production system.

Maintenance shutdowns on a continuous production facility are always high-pressure events.

We owe it to ourselves and our workforce to ensure that the necessary design, planning, and scheduling processes we employ support a professional, effective and safe event, reinstating the expected reliability and performance standards that minimize the total cost of ownership and maximize equipment performance.

Source: https://limblecmms.com/blog/continuous-production/